GRP Channel: Reinforcing Infrastructure with Strength and Versatility

GRP (Glass Reinforced Plastic) channels have emerged as essential components in various industries, providing a combination of strength, durability, and versatility. This article explores the composition, advantages, and diverse applications of GRP channels, highlighting their significance in reinforcing infrastructure and supporting critical operations.

Understanding GRP Channels:

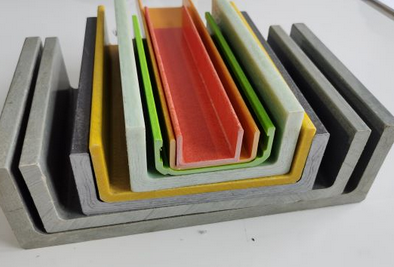

GRP channels, also known as fiberglass channels, are structural profiles manufactured using a composite material consisting of a matrix of resin reinforced with glass fibers. The combination of these materials results in a lightweight yet robust product that offers exceptional strength-to-weight ratio and resistance to corrosion, chemicals, and UV radiation.

Advantages of GRP Channels:

GRP channels offer several advantages that contribute to their widespread use in different sectors:

a. Strength and Durability:

Despite their lightweight nature, GRP channels possess impressive strength and structural integrity. They can withstand heavy loads, impact, and extreme weather conditions, making them suitable for demanding environments and long-lasting applications.

b. Corrosion Resistance:

GRP channels are highly resistant to corrosion caused by chemicals, moisture, and harsh environmental conditions. Unlike traditional materials such as steel or concrete, GRP channels do not rust or degrade, reducing maintenance requirements and extending the lifespan of infrastructure.

c. Lightweight and Easy Installation:

GRP channels are significantly lighter than traditional materials, making them easier to transport, handle, and install. This lightweight nature also reduces labor costs and allows for more efficient installation processes.

d. Versatility and Design Flexibility:

GRP channels can be manufactured in various shapes, sizes, and configurations to meet specific project requirements. They can be custom-designed to fit complex architectural or structural designs, providing flexibility and versatility in construction and infrastructure projects.

Applications of GRP Channels:

GRP channels find extensive applications across a wide range of industries:

a. Construction and Infrastructure:

GRP channels are commonly used in construction projects, including the reinforcement of bridges, tunnels, and walkways. They provide structural support, cable management, and drainage solutions. Their resistance to corrosion and lightweight nature make them ideal for coastal or high-moisture areas.

b. Electrical and Telecommunications:

GRP channels are widely employed in electrical and telecommunications industries for cable management and protection. They provide a safe and reliable conduit system for power cables, fiber optics, and other communication lines, ensuring efficient and organized routing of cables.

c. Water and Wastewater Treatment:

GRP channels are suitable for water and wastewater treatment facilities due to their corrosion resistance and ability to withstand harsh chemicals. They are used for constructing troughs, weirs, and flumes, providing efficient flow control and containment solutions.

d. Marine and Offshore Applications:

GRP channels are utilized in the marine and offshore industries due to their excellent resistance to saltwater, UV radiation, and harsh weather conditions. They are used for constructing jetty walkways, platform supports, and other marine structures.

Environmental Considerations:

GRP channels contribute to environmental sustainability in several ways. They are recyclable, reducing waste and promoting a circular economy. Their longevity and resistance to degradation also reduce the need for frequent replacements, further minimizing the environmental impact.

GRP channels have revolutionized infrastructure reinforcement and support systems, offering a lightweight yet robust solution for various industries. Their strength, durability, corrosion resistance, and design flexibility make them essential components in construction, electrical, water treatment, and marine applications. As industries continue to prioritize sustainable and long-lasting solutions, GRP channels are expected to play a pivotal role in reinforcing infrastructure and supporting critical operations for years to come.