pultrusion profile product defects and solutions

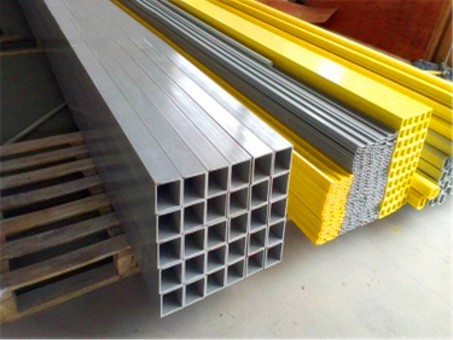

Nowadays, the figure of the pultrusion profile can be seen in the petrochemical industry or construction and electric power. As a material with higher anti-corrosion performance, high-temperature resistance, and insulation performance than steel, its extrusion molding process can be briefly divided into three steps: infiltration, molding, and curing/cooling, which is an automated process. In this process, if the improper operation or improper selection of raw materials, extrusion profile products will produce defects. This article lists some of the causes of defects intrusion profile products and solutions, for reference only:

(1) surface liquid droplets.

Reason: product curing is incomplete, fiber content, shrinkage, the product surface, and mold walls produce large gaps and uncured resin migration.

Measures: Increase the temperature or reduce the pulling speed so that it is fully cured, which is especially important for thick-walled products. Increase the yarn content or add a low shrinkage agent or filler.

(2) Surface peeling and breaking.

Cause: The surface-rich resin layer is too thick, crawling creep is produced at the detachment point, the difference between gel time and curing time is too large, and the detachment point is too far ahead of the curing point.

Measures: increase the yarn content to increase the pressure in the mold, adjust the initiation system, and adjust the temperature.

(3) White powder.

Reason: Poor mold release, mold wall sticking, debris accumulation scratching the product's surface, mold wall surface roughness value is too high (manufacturing reasons or use of scratches, rust corrosion).

Measures: choose a good release agent, clean up, repair or replace the qualified mold, shut down for a moment in the restart, and pull the debris out of the sticky mold, to achieve the purpose of cleaning.

(4) The parting line is wearing at the parting line.

Cause: The mold manufacturing size accuracy is insufficient to close the mold. When the module positioning deviation is large, the parting line has a sticky mold caused by the white line.

Measures: Repair the mold, disassemble it, and restart it after a few moments of the shutdown.

(5) The surface fiber is exposed, and the fiber is hairy.

Cause: This defect usually occurs only in products reinforced with fiber yarn, such as bars. The possible reason is that the fiber content is too high or resin debris is sticking to the mold cavity's inner wall.

Measures: Reduce the fiber content, suspend the machine and restart it.

(6) Not resistant to aging, easy to fade.

Reason: No light stabilizer and heat stabilizer added, poor light resistance of pigment.

Measures: add an anti-aging agent, and choose high-quality color paste.

(7) Poor insulation.

Reason:Poor insulation of resin and fiber, poor interface adhesion performance.

Measures: improve the choice of raw materials and use coupling agents to enhance the interface properties.

(8) insufficient strength and poor mechanical properties.

Reason: The mechanical properties of raw materials are low, and the degree of curing is not enough.

Measures: Select high-quality raw materials, such as high-strength fibers and high-strength resin, and reasonably control process parameters to ensure the degree of curing and post-curing treatment.

(9) dense porosity.

Cause: Poor quality of raw materials, temperature control is not reasonable.

Measures: Use good raw materials, and control the temperature can not be too high.

(10) Color spots, uneven color, discoloration.

Reason: Uneven mixing of pigment in resin, bad temperature resistance of pigment decomposition.

Measures: Strengthen the mixing, make the resin glue mixed evenly, replace the pigment, and type.

The above is the knowledge about the defects and solutions of pultrusion profile products. If you need more detailed information, welcome to contact us!