Do you know the advantages and application scope of pultrusion profile

How much do you know about the advantages and application scope of pultrusion profile? This article will introduce it to you.

1. High utilization of raw materials

Compared with traditional lay-up technology, pultrusion profileforming technology does not need to cut on the sheet fiber material or prepreg, and directly uses the raw wire and preg belt to produce, except for a small part at both ends of the profile that needs to be removed, no other wastes are generated during the production process.

2. It can produce complex structural profiles

In the engineering field, there are also winding technology and knitting technology which are suitable for the production of profiles. Due to the limitation of working principle, the above two technologies can only produce simple section profiles with a single cavity, and it is relatively difficult to arrange longitudinal reinforcing fibers. But the pultrusion profileforming technology can not effectively produce the variable section profile temporarily.

3.High productivity:

pultrusion profileforming technology for automated or semi-automated production lines, with“Forming” and“Curing” two functions, can achieve continuous production. pultrusion profilecan be up to 10 meters per minute, which is the other“Molding, curing” type of fiber composites production technology can not be compared.

4. Good quality

By means of automatic equipment, the winding pre-tension, longitudinal pre-tension, traction, resin injection pressure, die temperature distribution, pultrusion speed and other process parameters can be precisely controlled in the production process, so as to ensure the uniformity and controllability of the overall quality. In addition, when the section is cured, it is covered by an external die, and the overall dimension tolerance of the cured section is small, and the surface quality is high.

5. Be flexible

By using different fiber materials and substrate for collocation, pultrusion profilemolding technology can be based on different needs to produce suitable products.

6. Expand and replicate

By using the same process parameters, molds, raw materials, you can quickly ensure the same quality of the same conditions to complete the production line expansion or replication in other areas. Large-scale and high-quality profiles can be produced without experienced lay-up workers or high-cost autoclave equipment.

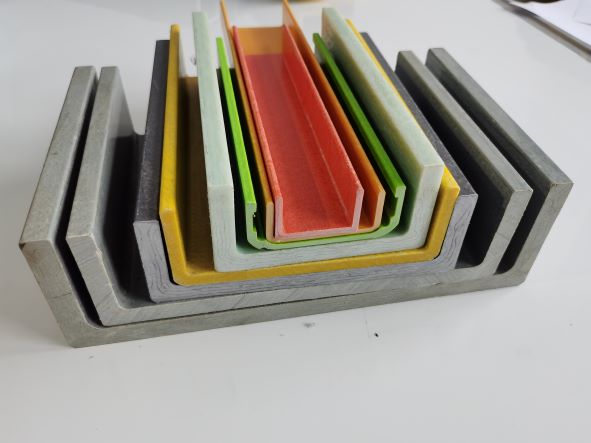

pultrusion profilemolding products application

pultrusion profileproducts include various rods, plates, hollow tubes and profiles, which are widely used, including the following aspects:

1.Electrical markets

2.chemical industry, anti-corrosion market

3. The consumer entertainment market

4. The construction market

5. Road traffic markets

6.The wind market