Is GFRP plate glass or metal

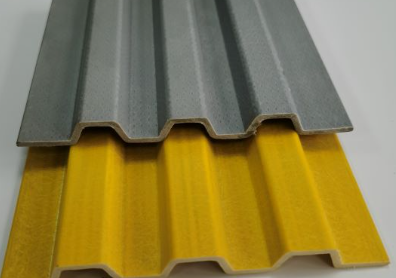

GFRP plate refers to the reinforced plastic with glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix, with glass fiber or its products as reinforcing material, called glass fiber reinforced plastic.

GFRP plate is like reinforced concrete, in which the glass fiber wire is the supporting steel, and the resin is like the binder cement.

GFRP plate is used everywhere in life, such as garbage cans on the street, benches in shopping malls, sculptures and play equipment in parks, etc.

Advantages of GFRP plate.

High strength and light weight

GFRP plate concentrates the characteristics of glass fiber and synthetic resin, the density is between 1.5~2.0, only 1/4~1/5 of ordinary carbon steel, and about 1/3 lighter than light metal aluminum. In contrast, do withstand a certain force of the product, with glass fiber reinforced plastic to do, than metal materials, product weight is much lighter. Some large landscape sculptures, using FRP to do, than the weight of metal to do much lighter, transport and installation is relatively safe a lot.

Strong corrosion resistance

GFRP plate is a good corrosion resistant material, with good resistance to atmosphere, water and general concentration of acid, alkali, salt and many kinds of oil and solvent.

Strong designability

The molding process can be flexibly selected according to the shape, technical requirements, usage and quantity of the product. The process is simple and can be molded in one go with outstanding economic effect.

FRP, which has replaced metal materials in many fields, also has a relatively significant drawback: deformation and aging. But the vast majority of materials have this problem.

In addition to a single fiber-reinforced plastic, there is a glass fiber reinforced cement, GRC: is the abbreviation of glass fiber reinforced cement, is the alkali-resistant glass fiber, cement, sand and other composite materials in a certain ratio of mixing, pouring in the mold molding, production of a rich shape, texture of a variety of products, is widely used in the characteristic architecture and sculpture.

The difference between GFRP plate and tempered glass

Tempered glass, also known as safety glass, is glass that has been tempered from ordinary flat glass or float glass, and is still essentially glass.

GFRP plate is a composite material with glass fiber and its products (glass cloth, tape, felt, yarn, etc.) as reinforcement material and synthetic resin as matrix material, which is essentially a kind of plastic.

The main manufacturing processes of GFRP sheets are

Hand lay-up molding process

A simple and mature molding process, its typical process is: on the mold coated with release agent, the resin mixture with curing agent and glass fiber fabric are laid by hand layer by layer, dipped in glue and eliminate air bubbles, laminated to a determined thickness, and then cured to form the part.

Spray Molding Process

It is a semi-mechanized molding process, which is an improvement of hand paste molding. It is to spray two polyester resins mixed with initiator and accelerator from both sides of the gun, while the cut glass fiber roving is sprayed from the center of the gun, so that it is evenly mixed with resin and deposited onto the mold; when deposited to a certain thickness, it is compacted with a roller to make the fiber soak the resin and eliminate the air bubbles, and then cured into products.

RTM molding process

Resin Transfer Molding is a closed mold molding technology improved by hand paste molding process, its basic principle is to put the glass fiber reinforced material into the closed mold cavity, inject the resin glue into the mold cavity with pressure, soak through the glass fiber reinforced material, then curing, after demoulding into products.

Pultrusion molding process

Continuous fiberglass bundles, strips or cloths impregnated with resinous glue are formed, cured and continuously produced into FRP profiles of unlimited length by extruding the die under the action of traction. This process is most suitable for producing various FRP profiles of the same cross-sectional shape, such as bars, tubes, solid profiles (I-beam, slotted, square profiles) and hollow web profiles (door and window profiles, blades, etc.), etc.

Thermosetting Molding

A certain amount of pre-treated molding material is put into the preheated mold and a high pressure is applied to fill the mold cavity with the molding material. Under a certain pressure and temperature, the molded material is gradually cured, and then the product is removed from the mold, and the necessary auxiliary processing is carried out to obtain the product.

Winding Forming

The pipe is produced with the cooperation of the rotating mandrel, the support rollers and the steel belt, and the actual size of the pipe is set according to the diameter of the pipe. After the winding is finished, the product is removed from the mold and finally cured at a certain temperature.

FRP products are also different from traditional material products, in performance, use, life properties greatly superior to traditional products, in aerospace, railroad, decorative architecture, home furniture, advertising display, craft gifts, building materials, sanitary ware, yacht berth, sports materials, sanitation engineering and many other industries, its easy to shape, customizable, color arbitrary deployment characteristics, favored by merchants and sellers, occupying a growing market share. Occupy an increasingly large market score.