Three major differences between fiberglass panels and aluminum substrates

fiberglass panels are made of glass fiber material and high heat resistant composite material, which does not contain harmful asbestos ingredients to human body. It has high mechanical and dielectric properties, good heat and moisture resistance, and good processability. It is used for plastic molds, injection molds, machinery manufacturing, molding machines, drilling machines, injection molding machines, motors, PCBs, ICT jigs, and bench top grinding pads.

The outside of fiberglass panels can be wrapped with cloth and leather to make beautiful wall and ceiling decoration, which is widely used. It has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection, flame retardant, etc.

1, the advantages of fiberglass panels

(1), has high mechanical properties and electrical resistance, also has good heat and moisture resistance, and good processability. Generally used in plastic molds and machinery manufacturing.

(2), injection mold molding usually requires: high temperature material and low temperature mold. The same machine condition must be used to insulate the method. Keep the injection mold low temperature at the same time can not make the injection molding machine temperature is too high. Installing insulated insulation between the injection mold and the injection machine can meet this requirement. Shorten the production cycle, increase productivity, reduce energy consumption, improve the quality of finished products, continuous production process to ensure stable product quality, prevent machine overheating, no electrical failure, no oil leakage in hydraulic system.

2、Use of fiberglass panels

(1),Construction industry: it can be used as cooling tower, building structure, indoor equipment and decorative parts, FRP flat panel, decorative panel, and solar energy utilization device, etc.

(2), Chemical industry: It can be used for corrosion resistant pipes, corrosion resistant pumps and their accessories, grilles, ventilation facilities and wastewater and sewage treatment equipment, etc.

(3), automobile and railroad transportation industry: it can be used as automobile shell and other parts of the device, as well as the body shell of large buses, doors, inner panels and instrument screens, etc.; in the road construction part, there are road signs, isolation piers and highway guardrails, etc.

(4), fiberglass panels performance, generally can be used for soft package base, outside and then wrapped with cloth, leather, etc., can be made into a beautiful wall and ceiling decoration.

(5), has the advantages of sound absorption, sound insulation, heat insulation, environmental protection, flame retardant, etc.. Good insulation characteristics, so it has been used in the shell of radar, but also good anti-corrosion materials, and now has been widely used in the chemical industry. Glass fiber board has the advantage of high plasticity.

Second, what is aluminum substrate

Aluminum substrate is a kind of metal-based copper laminate with good heat dissipation function, generally single panel consists of three layers of structure, respectively, circuit layer (copper foil), insulation layer and metal base layer. For high-end use there are also designed for double-sided panels, with the structure of circuit layer, insulation layer, aluminum base, insulation layer, circuit layer. Very few applications for multilayer board, can be made of ordinary multilayer board with insulation layer, aluminum base laminated.

1, the advantages of aluminum substrate

(1), Heat dissipation is significantly better than the standard FR-4 structure.

(2), The dielectric used is usually 5 to 10 times more thermally conductive than conventional epoxy glass and is only one-tenth as thick.

(3), The heat transfer index is more efficient than that of conventional rigid PCBs.

(4), can use lower copper weight than shown in the IPC recommendation chart.

2, the use of aluminum substrate

(1), Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

(1), Power supply equipment: Switching regulator, DC/AC converter, SW regulator, etc.

(1), Communication electronic equipment: high frequency amplifiers, filtering appliances, transmitting circuits.

(1), Office automation equipment: motor drivers, etc.

(1), Automobile: electronic regulator, ignition, power controller, etc.

(1), Computers: CPU boards, floppy disk drives, power supply units, etc.

(1), Power modules: converters, solid state relays, rectifier bridges, etc.

Aluminum substrates are widely used in general audio equipment, power supply equipment, communication electronic equipment, office automation equipment, automobiles, computers, and power modules.

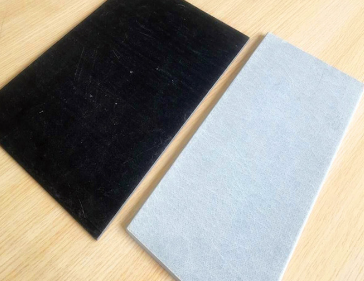

Three, fiberglass panels and aluminum substrate three major differences

1、Price

fiberglass panels and aluminum substrate in terms of price comparison, fiberglass panel price will obviously be much cheaper.

2、Process

In fiberglass panels according to the different materials and production processes can be divided into double-sided copper foil fiberglass panels, perforated copper foil fiberglass panels and single-sided copper foil fiberglass panels three, of course, different materials made of fiberglass panels in the price will be different.

3、Performance

Because the aluminum substrate has very good thermal conductivity, so the aluminum substrate heat dissipation performance is much better than fiberglass panels.