What is GRP tubes?

GRP tubes are called Glass Reinforced Plastic tubes which belong to the composite materials, made of resin matrix reinforced with glass fibers. High tensile strength, good corrosion resistance (withstands a high level of combustion gases and temperatures), lightweight — providing for use in various applications.

GRP tubes are normally manufactured by a pultrusion process, in which continuous glass fiber strands pass through a resin bath and then through forming die. The resin between layers is sealed and cured in the die producing a high fiber content tube with consistent reinforcement. These properties make it possible to produce tubes that have both a smooth outer surface and high end-bending and torsion performance.

It is one of the biggest benefits for GRP tubes that they owns high axial compressive strength by including short-cut glass fibers into resin matrix within themselves. It therefore greatly improves the tubes resistance to high pressures and means it can be used in applications such as pipe jacking or tunnel boring where the tube must retain its integrity underground.

GRP pipes are also renowned for their resistance to corrosion, which is why they're frequently used in chemical plants, wastewater treatment facilities and marine environments where conventional metals would rust furiously. Their lightweight also makes them easier to handle and install as opposed to metal pipes, thus saving on labour costs and installation time.

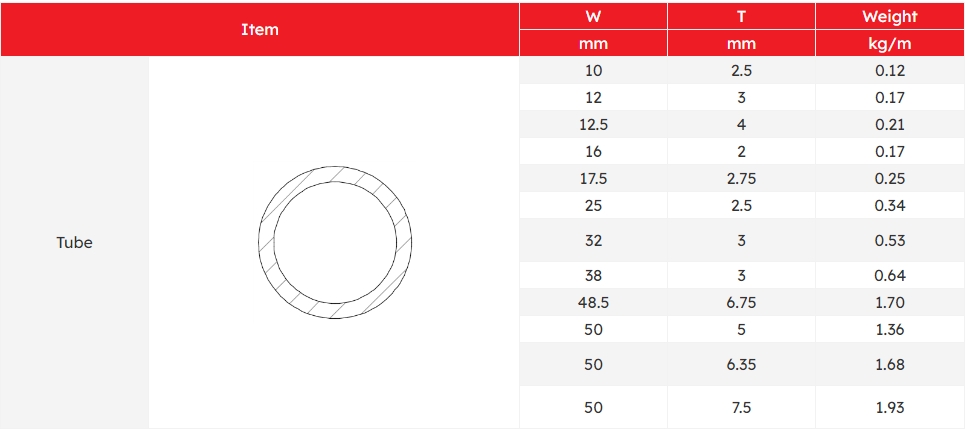

The GRP tubes can also be manufactured in numerous diameters and lengths, with the ability for some manufacturers to customize their products according to specific project needs. They are frequently stocked in standard lengths, like 5 meters long and can come in various colors (white or black for smaller diameter tubes), grey to white containing larger ones).

Materials: GRP tubes can be manufactured using different resin matrices (polyester, vinyl ester or acrylic- each offering varying properties/performance advantages) For example, some resins (such as vinyl ester) provide strong chemical resistance, where others (epoxy and acrylic) resist ultraviolet wavelengths better.

In total, GRP tubes are both a flexible and robust solution for sectors needing composite materials that are strong but also comparably lightweight and highly resistant to degradation. And as more engineers and specifiers realize the unmatched benefits over traditional materials, their usage in construction projects across transportation to infrastructure is growing.

Nanjing Hypro Composites Co., Ltd. GRP tubes are manufactured in a state-of-the-art production plant, using a variety of resin matrix and fiber reinforcement combinations to produce the highest quality pultruded composite profiles.

The experienced teams are always being challenged to improve when and where possible. Team leaders and supervisors are supporting the production team and offer support when required. The success of our hard work and commitment can be seen with increasing customer base and our attention to detail of our products.