What are the methods of installing fiberglass channel?

Applications of Fiberglass Channels

Construction: Fiberglass channels are used in various construction applications, including roofing, flooring, and structural support systems, due to their durability and resistance to corrosion.

Marine Industry: The marine industry benefits from fiberglass channels' resistance to saltwater and marine life, making them ideal for docks, piers, and boat components.

Industrial Settings: In industrial settings, fiberglass channels are used for walkways, platforms, and as structural supports in chemical plants and wastewater treatment facilities.

Agricultural: Fiberglass channels are used in agricultural buildings for their resistance to moisture and chemicals, as well as their lightweight properties for easy installation.

Electrical Insulation: Due to their non-conductive nature, fiberglass channels are used in electrical applications for insulation and safety.

Transportation: In the transportation industry, fiberglass channels are used for trailer bodies, truck beds, and other components that require lightweight and durable materials.

Benefits of Using Fiberglass Channels

Strength: Fiberglass channels have high tensile strength, making them capable of withstanding heavy loads.

Corrosion Resistance: They are resistant to corrosion from chemicals, saltwater, and other corrosive substances.

Lightweight: Being lightweight, fiberglass channels are easier to handle and install compared to heavier materials like steel.

Durability: With a long service life, fiberglass channels require minimal maintenance and are resistant to weathering.

Electrical Non-conductivity: They are non-conductive, making them safe for use in electrical applications.

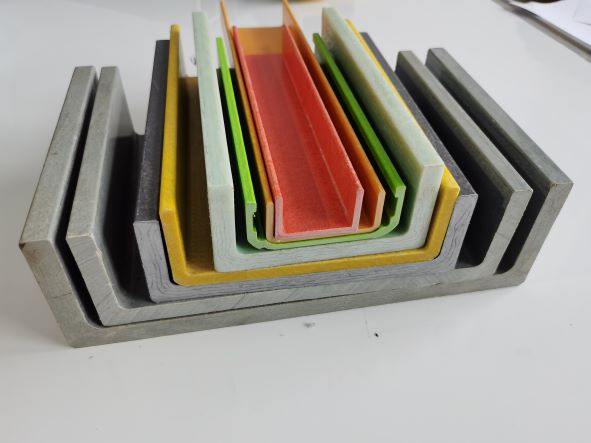

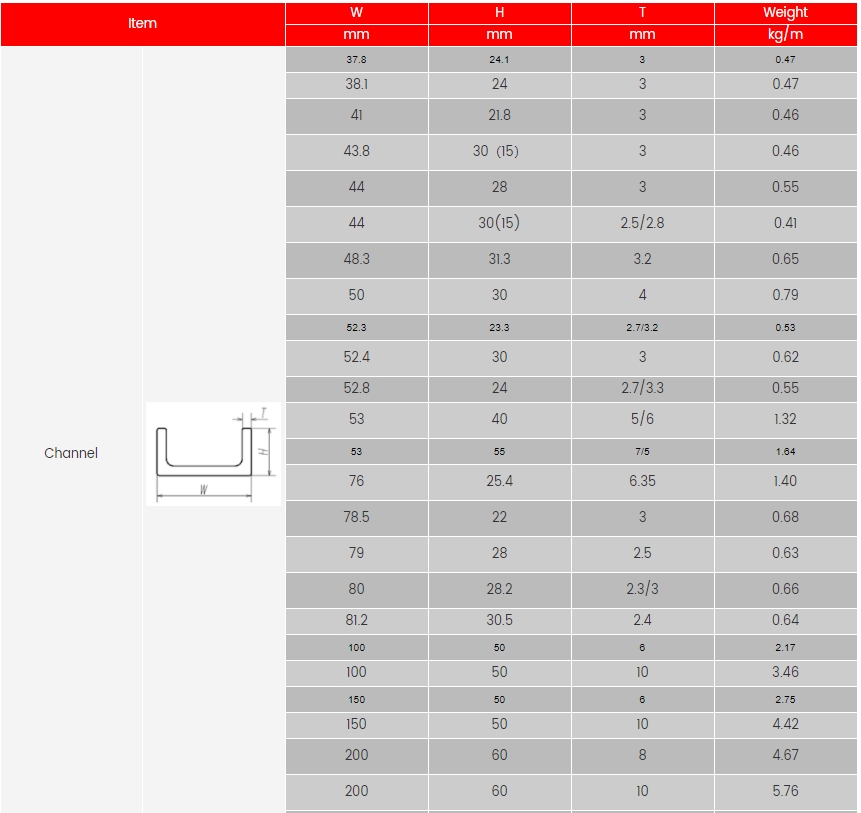

Customizability: Fiberglass channels can be manufactured in various sizes, shapes, and colors to meet specific project requirements.

Manufacturing Process of Fiberglass Channels

Molding: The manufacturing process begins with molding the fiberglass channels. This can be done using open molding techniques like hand lay-up or more automated processes like resin transfer molding (RTM).

Curing: After the molding process, the fiberglass channels are cured in a controlled environment to ensure the resin fully hardens and bonds with the glass fibers.

Trimming: Once cured, any excess material is trimmed to achieve the desired shape and dimensions.

Finishing: The channels may undergo a finishing process, such as sanding or polishing, to achieve a smooth surface.

Quality Control: Each batch of fiberglass channels is inspected for quality to ensure they meet industry standards.

Installation of Fiberglass Channels

Planning: Before installation, plan the layout and ensure all necessary tools and materials are available.

Preparation: Prepare the surface where the fiberglass channels will be installed, ensuring it is clean, dry, and free of any debris.

Cutting: If necessary, cut the fiberglass channels to the required length using appropriate tools like a fiberglass saw or power saw with a diamond blade.

Assembling: Assemble the fiberglass channels according to the project specifications, using appropriate fasteners and adhesives.

Securing: Secure the channels in place, ensuring they are properly aligned and fastened to prevent movement.

Sealing: Apply sealants as needed to prevent water infiltration and ensure a long-lasting installation.

Inspection: After installation, inspect the work to ensure the fiberglass channels are securely in place and free of any defects.