What are the advantages and disadvantages of fiber glass reinforced plastic

fiber glass reinforced plastic is based on the original pure plastic, adding glass fiber and other additives, so as to improve the scope of use of the material.

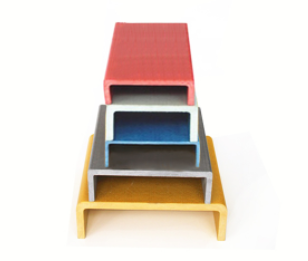

Product description.

Generally speaking, most of the fiber glass reinforced plastic is mostly used in the structural parts of products and is a structural engineering material; such as: PP, ABS, PA66, PA6, PC, POM, PPO, PET, PBT, PPS.

Product advantages.

1. Glass fiber is a high temperature resistant material, therefore, the heat resistance temperature of reinforced plastics is much higher than before without glass fiber, especially nylon plastics.

2. The addition of glass fiber restricts the mutual movement of polymer chains of plastics, therefore, the shrinkage of reinforced plastics decreases a lot and the rigidity is greatly improved.

3. The reinforced plastic will not stress crack, and at the same time, the impact resistance of the plastic is much improved.

4. Glass fiber is a high-strength material, which also greatly improves the strength of plastic, such as: tensile strength, compression strength, bending strength, much higher.

5. Due to the addition of glass fiber and other additives, the burning performance of the reinforced plastic decreases a lot, and most of the materials cannot be ignited, which is a kind of flame retardant material.

Product disadvantages.

1. Due to the addition of glass fiber, not adding glass fiber before is transparent, will become opaque.

2. The toughness of the plastic is reduced, and the brittleness is increased.

3. Due to the addition of glass fiber, the melt viscosity of all materials increases, the liquidity becomes poor, and the injection pressure increases a lot compared with that without adding glass fiber.

4. Due to the addition of glass fiber, the liquidity is poor, and the injection temperature of all reinforced plastics should be increased by 10℃-30℃ compared with that before without glass fiber in order to inject normally.

5. Due to the addition of glass fiber and additives, the hygroscopic properties of reinforced plastics are greatly enhanced, and the original pure plastics that do not absorb water will also become water-absorbent, therefore, injection molding should be into drying.

6. In the injection molding process, glass fiber can enter the surface of plastic products, making the surface of the products become very rough and spotty. In order to obtain high surface quality, it is better to use mold temperature machine to heat the mold when injection molding, so that the plastic polymer can enter the surface of the products, but it cannot reach the appearance quality of pure plastic.

7. After the glass fiber reinforced, glass fiber is a very hard material, the auxiliary high temperature volatilization is a very corrosive gas, the screw of the injection molding machine and injection mold wear and corrosion is very large, therefore, the production of such materials and injection molding machine, we should pay attention to the surface of the equipment anti-corrosion treatment and surface hardness treatment.

Product process

In terms of product performance, all the fiber glass reinforced plastic requires a certain length of cut glass fiber, generally between 0.4-0.8mm, in order to play a reinforcing role: glass fiber is too short, only the role of filling, and waste its reinforcing properties; glass fiber is too long, will be due to the interface between the glass fiber and the material is not well combined, and affect its reinforcing effect. If the glass fiber is too long, it will affect the strengthening effect because the interface between the glass fiber and the material is not well bonded, and the surface of the product is too rough and not smooth enough.