Professor Ma Songqi of Jiangnan University's Chem. Soc. Rev. Review: Closed-loop Recyclable Polymers - From Monomer and Polymer Design to Polymerization-Depolymerization Cycles

Plastics and other polymer materials play a vital role in modern society, but their widespread use consumes a large amount of limited and non-renewable fossil resources and generates a large amount of waste on land or in the ocean. Therefore, the recycling and reuse of polymer waste such as plastics has huge ecological and economic benefits. Closed-loop recyclable polymers have inherent recyclability and are easily and selectively depolymerized into high-purity monomers, which can be repolymerized into polymers with the same properties. They are considered to be the next generation of polymer recycling technology and have attracted increasing attention from academia and industry.

Recently, Professor Ma Songqi's team from the School of Chemistry and Materials Engineering of Jiangnan University published a review academic paper entitled "Closed-loop recyclable polymers from monomer and polymer design to polymerization-depolymerization cycle" (Chem. Soc. Rev., 2024, DOI: 10.1039/D4CS00663A) in Chemical Society Reviews (2023 impact factor IF = 46.2), an international top chemistry journal founded by the Royal Society of Chemistry. This review elaborates on the influence of monomer structure design on polymer closed-loop recycling, and systematically explains the mechanism of monomer polymerization and depolymerization of the prepared polymer. In addition, the article comments on the impact of the development of closed-loop recyclable polymers on the environment, economy, and resources, points out the importance of developing closed-loop recyclable material science, and puts forward prospects for the future development of closed-loop recyclable polymers. Among them, Yang Shuaiqi, a 2023 doctoral student at the School of Chemistry and Materials Engineering of Jiangnan University, is the first author of this paper, and Professor Ma Songqi is the corresponding author.

Figure 1: Graphic Abstract (Development of closed-loop recyclable polymers is conducive to the green and sustainable development of polymer materials such as plastics)

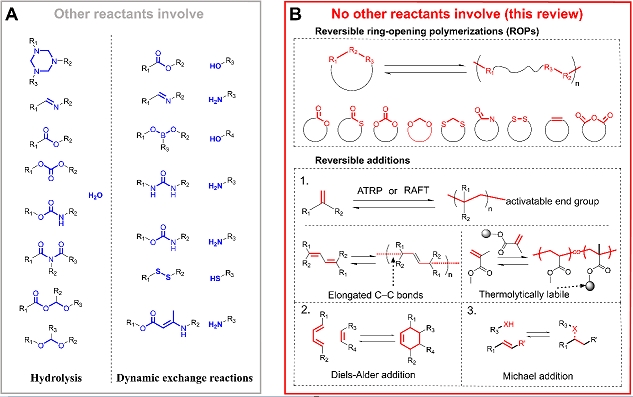

First, the closed-loop recyclable polymers are divided into two categories according to whether other small molecules need to participate in the depolymerization process (as shown in Figure 2).

Unlike closed-loop recyclable polymers based on hydrolysis and dynamic exchange depolymerization that require the participation of small molecules, this review mainly summarizes the research progress of closed-loop recyclable polymers based on reversible ring-opening polymerization and reversible addition polymerization that do not require the participation of other small molecules. For the convenience of summary and discussion, according to different monomers such as lactones, thiolactones, cyclic carbonates, hindered olefins, cycloolefins, thermally unstable olefin comonomers, cyclic disulfides, cyclic (thio) acetals, lactams, Diels-Alder addition monomers, Michael addition monomers, anhydride-secondary amide monomers, cyclic anhydride-aldehyde monomers and end-group activated polymers, they are divided into many subcategories.

Figure 2: Recyclable polymers based on reversible covalent bonds or chemistry: (A) Depolymerization requires the participation of other small molecules (such as hydrolysis, alcoholysis, aminolysis, etc.); (B) Depolymerization does not require the participation of other small molecules (this review)

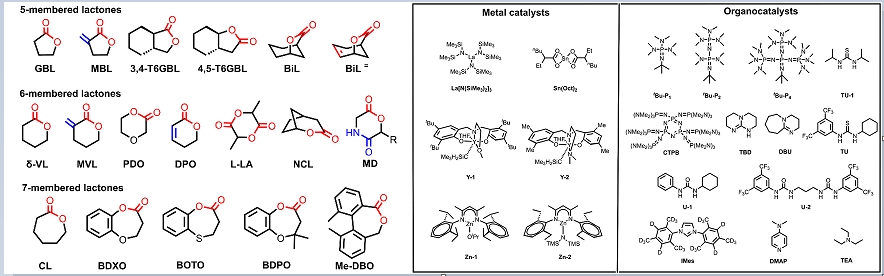

Secondly, the polymerization/depolymerization mechanism, monomer structure (cyclic lactone structure as shown in Figure 3), evolution of polymerization/depolymerization conditions (catalyst structure as shown in Figure 3), and corresponding polymerization conversion rate, polymer molecular weight, polymer properties, monomer recovery rate of each type of closed-loop recyclable polymer were summarized and discussed, and the progress and shortcomings of each type of closed-loop recyclable polymer were summarized.

Figure 3: Lactone monomer structure (left) and polymerization and depolymerization catalysts (right)

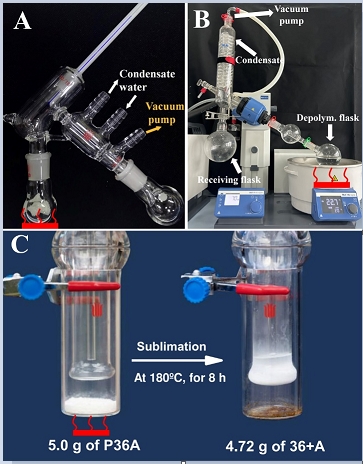

Considering the importance of depolymerization devices, this review summarizes and discusses the depolymerization devices separately (Fig. 4). During the depolymerization process, depolymerization and polymerization are a balanced reaction. If monomers are continuously extracted from the system, the reaction will continue to proceed in the direction of depolymerization, so that a high depolymerization rate can be obtained, and even 100% depolymerization of the polymer can be achieved. monomer. Therefore, a suitable depolymerization device can not only obtain high-purity monomers, but also significantly increase the monomer recovery rate.

Figure 4: Reported laboratory devices that can achieve high depolymerization rates: (A) short-path vacuum distillation device; (B) rotary evaporator; (C) sublimation device

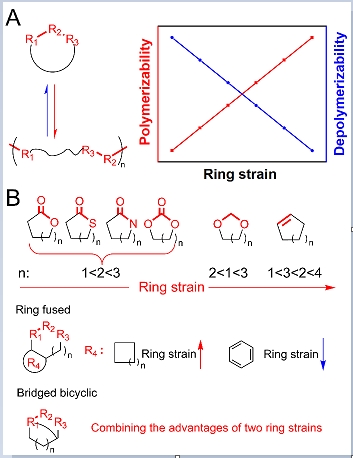

In the final summary, the authors summarized the polymerization of various monomers and the depolymerization of the corresponding closed-loop recyclable polymers, in which the polymerization and depolymerization of cyclic monomers are related to the size of the monomer ring tension (Figure 5). Each type of closed-loop recyclable polymer involved in this review was compared. Finally, the challenges and future development directions of closed-loop recyclable polymers are also pointed out: 1) Balance between polymerization and depolymerization; 2) Balance between depolymerization and performance; 3) No (or low) by-products in the recycling process; 4) Acceptable recycling costs; 5. Closed-loop recyclable polymers based on renewable resources; 6. Reusable depolymerization catalysts; 7) Industrial research.

Figure 5: Relationship between different monomer structures and polymerization/depolymerization. (A) Ring-opening polymerization and depolymerization of cyclic monomers and their polymers, and the correlation between ring tension and polymerization and depolymerization; (B) Factors affecting the ring tension of lactone, thiolactone, cyclic carbonate, lactam, cyclic acetal and cyclic olefin monomers