How do you make a pultrusion profile?

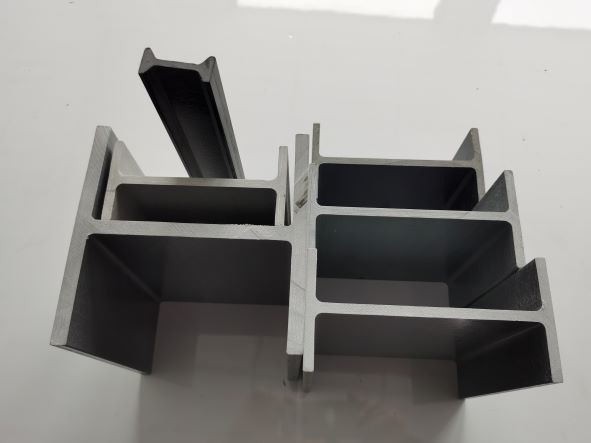

Pultrusion profile is an environmentally friendly manufacturing option that produces far fewer contaminants than many alternatives. It is also cost-effective and efficient, making it widely attractive. Pultrusion can produce FRP profiles (instead of steel products such as FRP Square Tubes, FRP round tubes, FRP channels, etc.) so how do you make a pultrusion profile?

1. Feed the fiber-reinforced material into the guide rail

The extrusion process involves pulling the fiber-reinforced material through heating die. These materials are usually continuous mats and filaments (also called rovings). The first step in the process is to feed the raw materials into the guide rail. This has to be done very carefully, as inaccuracy can harm the final outline. A large number of fiber inputs come together to create parts. The tension in the guideway forms the material.

2. Resin impregnation

Once gathered together in the guiding device, the reinforcing fibers are impregnated with resin. Traditionally, this has been accomplished by moving the fibers through a polymer tank. The tank is usually composed of resin, pigment, filler, and a curing catalyst. In some cases, the resin is injected into the heated mold.

3. Heat the mold

After passing through the soaking bath, the reinforcing fibers pass through the heated mold. This is the process by which the fiber begins to solidify into its final shape, as the heat initiates the cross-linking process within the impregnated reinforcements. A key consideration in this step is temperature. Low temperature will lead to the weak profile of the composite, while the high temperature will lead to the cracking of the composite.

4. Detach from the mold

At the end of the heating process, the resin temperature will become higher than the mold temperature. This starts the separation process. The manufacturer uses a tractor to pull the cured profiles out of the mold. After separation, the profile can be cut to a suitable length and reprocessed if necessary.

NHC is a global manufacturer of FRP composites. If you need a pultrusion profile, feel free to contact us for a more secure and sustainable customized product solution for customers around the world.